Quadratic assignment problem: Difference between revisions

| Line 7: | Line 7: | ||

Joe Szczerba and Tom Kueny to provide. | Joe Szczerba and Tom Kueny to provide. | ||

== Example == | == Numerical Example == | ||

Consider the QAP of placing 3 facilities in 3 locations. Let the distance and flow matrices be defined respectively as <math> | Consider the QAP of placing 3 facilities in 3 locations. Let the distance and flow matrices be defined respectively as <math>D=\begin{bmatrix} 0 & 5 & 6 \\ 5 & 0 & 3.6 \\ 6 & 3.6 & 0 \end{bmatrix} | ||

</math>, <math display="inline"> | </math>, <math display="inline">F=\begin{bmatrix} 0 & 10 & 3 \\ 10 & 0 & 6.5\\ 3 & 6.5 & 0 \end{bmatrix} | ||

</math> | </math>. | ||

There are <math>3! = 6</math> permutations of the 3 facilities in the 3 locations. The set of these permutations is typically denoted <math>S_3 </math> | For each pair <math>(i,j)</math>, <math>D_{i,j}</math> represents the distance between locations <math>i</math> and <math>j</math>. <math>F_{i,j}</math> represents the required flow (of supplies, products, etc.) between facilities <math>i</math> and <math>j</math>. The optimal solution will be the arrangement of the 3 facilities in the 3 locations so that the total flow over distance is minimized. Intuitively, the product of distance and flow represents cost, and the objective is to minimize this cost. Ideally, two facilities with lots of flow (more product or supplies) between the two should be placed closer together than two facilities that rarely interact (low flow). | ||

There are <math>3! = 6</math> permutations of the 3 facilities in the 3 locations. The set of these permutations is typically denoted <math>S_3 </math>. As an example, the permutation <math>\phi=(3 2 1)</math> represents facility 3 being placed at location 1, facility 1 at location 2 and facility 2 at location 3. Each permutation can be assigned a permutation matrix. The permutation matrix of <math>\phi </math>can be written as <math>X_{\phi} = \begin{bmatrix} 0 & 0 & 1 \\ 1 & 0 &0 \\ 0 &1 & 0 \end{bmatrix}</math>. The operation <math>X_{\phi}DX_{\phi}^{T} </math> permutes the distance matrix values so that <math>D_{i,j}</math> represents the distance between facilities <math>i</math> and <math>j</math> if the facilites are arranged according to the permutation <math>\phi</math>. | |||

The problem can be stated as | |||

== Applications == | == Applications == | ||

Revision as of 17:33, 21 November 2020

Author: Thomas Kueny, Eric Miller, Natasha Rice, Joseph Szczerba, David Wittmann (SysEn 5800 Fall 2020)

Introduction

Theory, Methodology, and/or Algorithmic Discussions

Joe Szczerba and Tom Kueny to provide.

Numerical Example

Consider the QAP of placing 3 facilities in 3 locations. Let the distance and flow matrices be defined respectively as Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle D=\begin{bmatrix} 0 & 5 & 6 \\ 5 & 0 & 3.6 \\ 6 & 3.6 & 0 \end{bmatrix} } , Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\textstyle F=\begin{bmatrix} 0 & 10 & 3 \\ 10 & 0 & 6.5\\ 3 & 6.5 & 0 \end{bmatrix} } .

For each pair Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle (i,j)} , Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle D_{i,j}} represents the distance between locations Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle i} and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle j} . Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle F_{i,j}} represents the required flow (of supplies, products, etc.) between facilities and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle j} . The optimal solution will be the arrangement of the 3 facilities in the 3 locations so that the total flow over distance is minimized. Intuitively, the product of distance and flow represents cost, and the objective is to minimize this cost. Ideally, two facilities with lots of flow (more product or supplies) between the two should be placed closer together than two facilities that rarely interact (low flow).

There are permutations of the 3 facilities in the 3 locations. The set of these permutations is typically denoted Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle S_3 } . As an example, the permutation Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \phi=(3 2 1)} represents facility 3 being placed at location 1, facility 1 at location 2 and facility 2 at location 3. Each permutation can be assigned a permutation matrix. The permutation matrix of Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \phi } can be written as . The operation permutes the distance matrix values so that Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle D_{i,j}} represents the distance between facilities Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle i} and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle j} if the facilites are arranged according to the permutation Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle \phi} .

The problem can be stated as

Applications

Natasha Rice and David Wittmann to provide.

The Backboard Wiring Problem

As the quadratic assignment problem is focused on minimizing the cost of traveling from one location to another, it is an ideal approach determining placement of components in many modern electronics. Leon Steinberg proposed a QAP solution optimize the layout of elements on a blackboard by minimizing the total amount of wiring required.

When defining the problem Steinberg states that we have a set of n elements

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle E = \left \{ E_{1}, E_{2}, ... , E_{n}\right \}}

as well as a set of r points

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle P_{1}, P_{2}, ... , P_{r}} where Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle r \geq n}

In his paper he derives the below formula:

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle min \sum_{1\leq i \leq j \leq n }^{} C_{ij}(d_{s(i)s(j))})}

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle C_{ij}}

represents the number of wires connecting components Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle E_{i}}

and Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle E_{i}}

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle d_{s(i)s(j))}} is the length of wire needed to connect tow components if one is placed at Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle P_{\alpha}} and the other is placed at Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle P_{\beta}} . If Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle P_{\alpha}} has coordinates Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle (x_{\alpha}, y_{\alpha}, z_{\alpha})} then Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle d_{s(i)s(j))}} can be calculated by

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle d_{s(i)s(j))} = \surd(\bigl(x_{\alpha} - x_{\beta}\bigr)^{2} + \bigl(y_{\alpha} - y_{\beta}\bigr)^{2} + \bigl(z_{\alpha} - z_{\beta}\bigr)^{2}) }

Failed to parse (SVG (MathML can be enabled via browser plugin): Invalid response ("Math extension cannot connect to Restbase.") from server "https://wikimedia.org/api/rest_v1/":): {\displaystyle s(x)} represents a particular placement of a component.

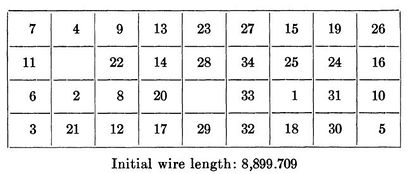

In his paper Steinberg a backboard with a 9 by 4 array, allowing for 36 potential positions for the 34 components that needed to be placed on the backboard. For the calculation he selected a random initial placement of s1 and chose a random family of 25 unconnected sets.

The initial placement of components is shown below:

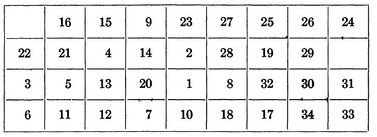

After the initial placement of elements it took an additional 35 iterations to get us to our final optimized backboard layout. Leading to a total of 59 iterations and a final wire length of 4,969.440.

Hospital Layout

Campus Building Arrangement

Molecular Confrontation Problem

Conclusion

References

- Alwalid N. Elshafei. Hospital Layout as a Quadratic Assignment Problem. Operational Research Quarterly (1970-1977). 1977;28(1):167. doi:10.2307/3008789

- Dickey JW, Hopkins JW. Campus building arrangement using topaz. Transportation Research. 6(1):59-68. doi:10.1016/0041-1647(72)90111-6

- Leon Steinberg. The Backboard Wiring Problem: A Placement Algorithm. SIAM Review. 1961;3(1):37.

- Phillips AT, Rosen JB. A quadratic assignment formulation of the molecular conformation problem. Journal of Global Optimization: An International Journal Dealing with Theoretical and Computational Aspects of Seeking Global Optima and Their Applications in Science, Management, and Engineer. 1994;4(2):229. doi:10.1007/bf01096724

- https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.217.1914&rep=rep1&type=pdf