Wing shape optimization

Authors: Santiago Correa, Jeet Dhoriyani, Joshua Krsek (jpk254), Aayush Singh, & Jeremy Wang (jw2363) (SYSEN/CHEME 6800 Fall 2021)

Introduction

The aerodynamic performance of a given body is maximized using an aerodynamic shape optimization method. This process can be thought of as minimizing the cost of total fuel consumption and maximizing the total lift of an aircraft by a method known as Wing Shape optimization. The aerodynamic performance is evaluated using software packages like computational fluid dynamics and the optimization can be done using a number of algorithms like Adjoint Method, Direct Sensitivity Analysis and Finite Differences. The wing shape problem is an application under the aerodynamic shape optimization method. An Adjoint method also known as gradient-based method is often used for shape optimization which is capable of computing objective function sensitivities based on the design parameters and variables of the shape under investigation. Methods like Direct Sensitivity Analysis and Finite Differences underperforms when compared to the Adjoint-Method when it comes to the aerodynamic shape optimization There are two different forms of Adjoint-Method namely, the continuous and discrete one. The discrete formulation is used for the purpose of explanation in this wiki.The Discrete-Adjoint Method used for the aerodynamic optimization aims at computing the gradient of the objective function F with respect to the design variable. The Adjoint-Method uses a computational fluid dynamics software package for the optimization method as the computation can get complicated. A numerical example and its explanation is provided later in this wiki-page.

Theory, methodology, and/or algorithmic discussions

Numerical example

We discuss a numerical example of wing shape optimization using a modern cutting approach comprising of computational fluid dynamics (CFD), a gradient based optimizer, and adjoint method to compute the necessary gradients for efficient airflow from the MDO Lab under PI Joaquim R. R. A. Martins at the University of Michigan <ref name=":1">

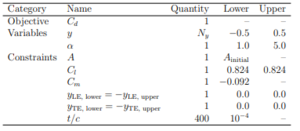

Problem Formulation

As the objective of this problem statement is to minimize the drag, $C_d$, of an RAE 2822 airflow in transonic, turbulent flow, this may be solved under the following design variables. $C_m$ and $C_l$ refer to the moment and lift coefficient. The lift coefficient is constrained to $C_l$ =0.824, and the moment coefficient about the quarter chord must be higher than $C_m$ =-0.092. The airfoil area must be no less than the initial area [4]. The area, $A$, of airflow is constrained from exceeding the area of the baseline airflow $A_initial$. The mesh was also determined to have 32,768 cells.

Methodology and Optimization Formulation

[1] introduces an original adaptive parameterization and discusses their mesh deformation, CFD solver, and numerical optimization. They used a free-foam deformation (FFD) method for its versatility in compute local and global changes capable of handling and starting with any baseline geometry. The paper utilizes two approaches for mesh deformation: the first using the pyWrap package is able to handle small changes and the second using the IDWarp package is able to handle large shape deformations across tightly-spaced points. The CFD solver used is ADflow, which includes a discrete adjoint method that can efficiently compute the derivatives of objective and constraint functions with respect to the many design variables [1]. For numerical optimization, Sparse Nonlinear OPTimizer (SNOPT) was used as its sequential quadratic programming (SQP) approach allows it to approximate the Hessian matrix using a quasi-Newton method. A mesh convergence test is performed to ensure the results of analysis are not influenced by changes in the size of the mesh [3].

Results

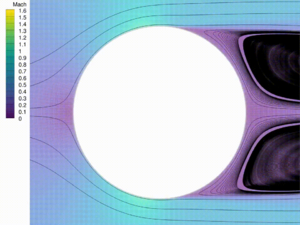

As seen in the video below, the algorithm starts from a circle and uses their shape optimization techniques to automatically get the modern supercritical airfoil. This solution represents the result of three optimization problems: 1. Drag minimization for a low air speed. 2. Adding a lift constraint, and 3. Changes of speed to high speed [1].

In this RAE 2822 case, they managed to obtain a reduction of 88.66 drag counts, which is comparable to the drag reductions reported in published literature while also showing less scatter. As the RAE 2822 case problem can expose issues related to gradient accuracy and flow solver failure due to separation interaction, the authors believe the use of the turbulence model in the adjoint-based gradient computation is necessary for obtaining well-converged optimization results. A unique challenge taken on by this paper is obtaining their optimal airflow starting from a circle. This challenge is taken to demonstrate their approach to converge to the optimal airflow starting from a “blank slate.” By obtaining this result, the paper shows the robustness in their numerical methods and effectiveness of using adaptive FFD parameterization. They also discovered that their FFD method results in a monotonic decrease in the minimum drag as the number of design variables increases, which shows scalability [1].

Applications

[1] Aircraft Wing Shape Optimization for Wing Mounted Models Wing-mounted configuration is very common in modern civil aircraft because of many advantages. For example, the wings structure is unloaded by the engine’s weight in flights, and the passenger cabin gets a low noise level. Furthermore, this configuration also contributes to the easy maintenance and replacement of the power systems. For Given Wing shape the Gradient-based optimization system is commonly used. The CFD mesh and FFD block is generated, and they are passed to the optimizer to define the aerodynamic optimization problem, such as drag minimization with respect to lift. The discrete-Adjoint Method is chosen to fulfill the complex aerodynamic optimization. problems. After the optimization problem is defined, the design variables vector is determined by the optimizer and passed to the shape parameterization module to produce a new surface mesh. [7]

[2] Blended wing body optimization for Unmanned Aerial Vehicle(UAV) In recent years, in order to reduce fuel consumption and improve performance, the optimization of UAV shapes has been the main focus of the competitive aerospace market.The development of Blended Wing Body (BWB) design is such an effort. In addition to the elimination of the tail for this particular kind of UAV and the significant reduction in equivalent weight, drag force, and radar cross-section, the available space for installing equipment inside the wing and the effective range have also been increased. [6]

[3] Drone Propeller Topology Optimization The propeller is a type of fan that converts mechanical energy into thrust power by accelerating the propulsive fluid. A drone propeller optimized the geometry to achieve greater efficiency and therefore longer life of multirotor adopts these propellers. Optimized Propeller designs also help in saving the battery life of Electric Drones.[8]

[4] Wind Turbine Blade Optimization An aerodynamically efficient blade is the prime necessity to extract maximum power from a wind turbine. With the increasing size of the wind turbine blade, the blades are now basically made of composite materials. In the research on the structure of wind turbine blades, the study of structural testing and simulation of the wind turbine blade. The overall goal is to reduce the cost price of the produced power, and as long a size increase results in lowering the cost price, the trend will continue. However, another way of capturing more wind energy is to improve the aerodynamic efficiency of the energy conversion, such as maximizing the power coefficient and the energy yield of wind turbines. [9]