Wing shape optimization

Authors: Santiago Correa, Jeet Dhoriyani, Joshua Krsek (jpk254), Aayush Singh, & Jeremy Wang (jw2363) (SYSEN/CHEME 6800 Fall 2021)

Introduction

Theory, methodology, and/or algorithmic discussions

Numerical example

We discuss a numerical example of wing shape optimization using a modern cutting approach comprising of computational fluid dynamics (CFD), a gradient based optimizer, and adjoint method to compute the necessary gradients for efficient airflow from the MDO Lab under PI Joaquim R. R. A. Martins at the University of Michigan <ref name=":1">

Problem Formulation

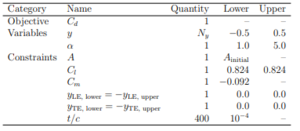

As the objective of this problem statement is to minimize the drag, $C_d$, of an RAE 2822 airflow in transonic, turbulent flow, this may be solved under the following design variables. $C_m$ and $C_l$ refer to the moment and lift coefficient. The lift coefficient is constrained to $C_l$ =0.824, and the moment coefficient about the quarter chord must be higher than $C_m$ =-0.092. The airfoil area must be no less than the initial area [4]. The area, $A$, of airflow is constrained from exceeding the area of the baseline airflow $A_initial$. The mesh was also determined to have 32,768 cells.

Methodology and Optimization Formulation

[1] introduces an original adaptive parameterization and discusses their mesh deformation, CFD solver, and numerical optimization. They used a free-foam deformation (FFD) method for its versatility in compute local and global changes capable of handling and starting with any baseline geometry. The paper utilizes two approaches for mesh deformation: the first using the pyWrap package is able to handle small changes and the second using the IDWarp package is able to handle large shape deformations across tightly-spaced points. The CFD solver used is ADflow, which includes a discrete adjoint method that can efficiently compute the derivatives of objective and constraint functions with respect to the many design variables [1]. For numerical optimization, Sparse Nonlinear OPTimizer (SNOPT) was used as its sequential quadratic programming (SQP) approach allows it to approximate the Hessian matrix using a quasi-Newton method. A mesh convergence test is performed to ensure the results of analysis are not influenced by changes in the size of the mesh [3].

Results

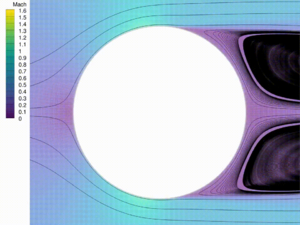

As seen in the video below, the algorithm starts from a circle and uses their shape optimization techniques to automatically get the modern supercritical airfoil. This solution represents the result of three optimization problems: 1. Drag minimization for a low air speed. 2. Adding a lift constraint, and 3. Changes of speed to high speed [1].

In this RAE 2822 case, they managed to obtain a reduction of 88.66 drag counts, which is comparable to the drag reductions reported in published literature while also showing less scatter. As the RAE 2822 case problem can expose issues related to gradient accuracy and flow solver failure due to separation interaction, the authors believe the use of the turbulence model in the adjoint-based gradient computation is necessary for obtaining well-converged optimization results. A unique challenge taken on by this paper is obtaining their optimal airflow starting from a circle. This challenge is taken to demonstrate their approach to converge to the optimal airflow starting from a “blank slate.” By obtaining this result, the paper shows the robustness in their numerical methods and effectiveness of using adaptive FFD parameterization. They also discovered that their FFD method results in a monotonic decrease in the minimum drag as the number of design variables increases, which shows scalability [1].